- Outdoor lighting solution

- Indoor lighting solution

- Smart power solution

- The integrated management solution of municipal administration The municipal tunnel drainage management solution The intelligent management solutions of PV plants The automation solution of low-voltage distribution Intelligent village comprehensive management solution Industrial / enterprise energy efficiency management solutions

- The classic cases

- The intelligent management solutions of PV plants

Since 2002, our country implemented the project "power to the countryside" in the western region.Our country has being built a large amount of solar energy grid-connected PV plants in northwest China.As a result of these power stations were built in remote rural pastoral area, where have a poor condition of environment and traffic.These make the work of PV plants more difficult.

In terms of the current management experience of solar PV plants , in order to ensure the safety,profit and efficient operation of PV generation system, the construction of a set of real-time monitoring, centralized management, intelligent early warning analysis and disaster prevention for the integration of PV plants integrated management system is important to establish a standardized and effective management mechanism for PV plants, especially ensure efficient operational and management of the PV plants.

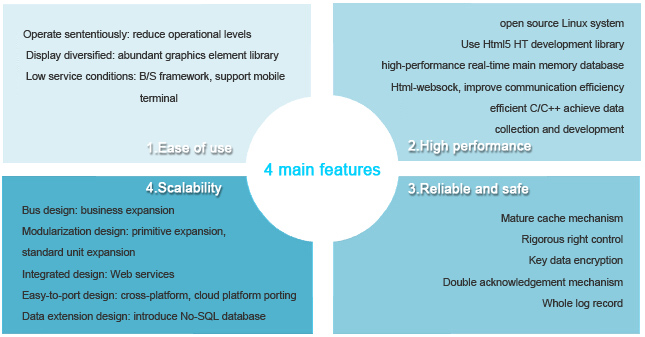

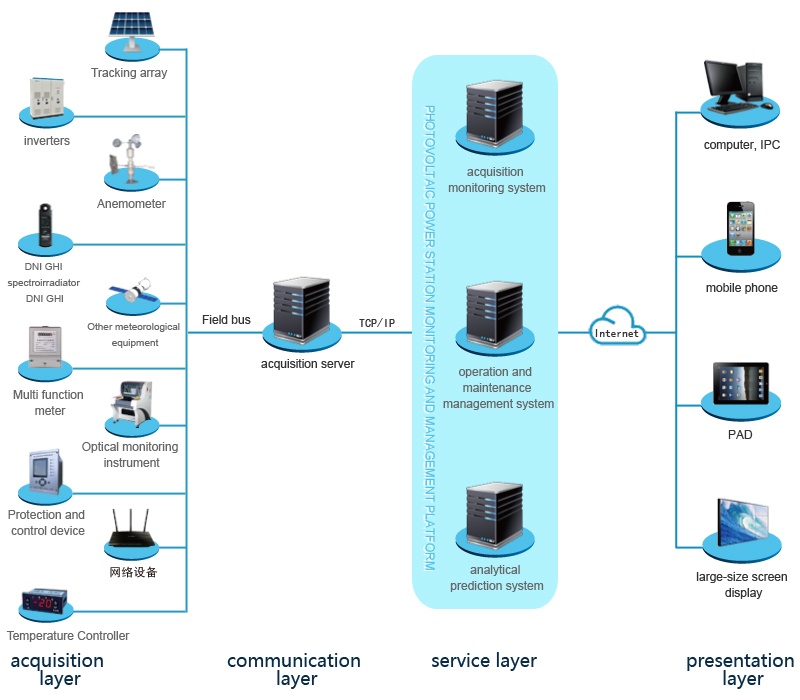

The pv power station integrated management solution of FCREAT is designed to provide intelligent management tools for PV enterprise.By means of collecting, transmitting,saving and processing information and intelligent analysis forecast the data of PV power station make the managers can predict events more accurately that may occur in power plant operation management, scheduling resources in a timely manner and to take timely and effective guidance, prevention and treatment measures, keep efficient and effective operation of the PV plants.

1. To reduce costs: by means of information technology work together with other resources, effectively integrating power generation equipment assets, thus reducing the resource consumption and waste of PV production and management and the cost of site of station building and running.

2. Efficient production: based on the information fusion,photoelectric power station integrated management platform can promote station to total organic collaboration and avoid information island, so as to achieve efficient production collaboration.

3. The safety of disaster prevention: take the customer as this is to create a product design, research and development of the foothold, the FCREAT photoelectric management platform to implement safety electric power dispatching station, combining with management to achieve the purpose of disaster prevention.

4. Reasonable management: the FCREAT photoelectric management platform do information mining and trend analysis for the customer continuously , resulting in power station work and plan the basis of the decision-making basis, to achieve the target of improve the management level for power station.

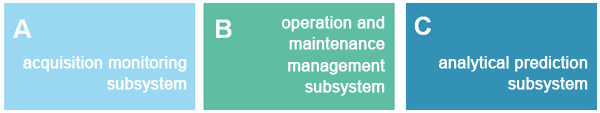

The intelligent management solutions of PV plants is composed of the following three modules

【A acquisition monitoring subsystem】

1 Data real-time collection: (1) real-time collection of global equipments: such as tracking array, inverter, meteorological station, anemograph, DNI, GHI, electricity meter, optical monitoring instrument and network equipment. Make continuous data collection for outdoor test base power station. (2) Abundant protocol libraries: Modbus RTU/TCP, IEC 101, IEC 102, IEC 103, IEC 104, CDT

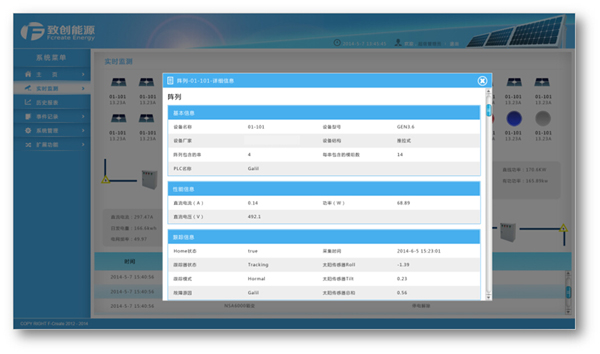

2 Real-time monitoring management: observe the operational aspect and state of global equipments continuously, and can be showed by image, sheet, trend curve chart, pie chart, histogram, etc.

3 Remote operation monitoring and controlling: remote monitor integral operational aspect, remote monitor operational aspect of standard cell, remote control equipments. Also known as remote signaling, remote metering, remote control.

4 Data store-and-forward: stored data includes record data, real time data, and historical data. Store and transmit local sunlight, temperature, wind speed and wind direction, and other meteorological information. And monitor, record, store and transmit operation parameters and operation states of modules.

5 Mobile monitoring management: real-time look over operation state of power station, u operational aspect and statistical analysis performance data of unit and array via mobile terminal (mobile phone, tablet PC).

【B operation and maintenance management subsystem】

1 System management: (1) daily functions: user management, resource management, safety management, log management, configuration management (2) practical miscellaneous functions: work order management, work order plan, knowledge base (FAQ and malfunction) help and management

2 Device layout: communication link configuration, standard cell configuration, data and linkage configuration of standard cell

3 Monitoring page configuration: provide data association via mechanism based on pixel

4 Alarm events linkage: when receive the alarm information of real-time event, remind operation staff with linkage based on strategy, such as sound-light alarm, short-message warming.

5 Log operation tracking: the system can record users’ log-in information automatically, such as log-in user, log-in time, exit time, and operated functions. And also can record the processed time, data range, and executive condition of data entry, data synchronization, data extractions, data analysis and other applications automatically, convenient for tracking and auditing when the system goes wrong.

【C analytical prediction subsystem】

1 Analytic and statistics of statement: do statistical analysis of the real-time state and historical data in the field. Generate statistical analysis and statement of field failure events rapidly.

2 Statistic analysis of data: do statistical analyze of electricity generation’s situation and operational aspect, such as generating capacity, operational days, saved standard coal, CO2 emission reductions, etc., and then support operational analysis of power generation enterprises, satisfy the demand of data analysis and process for power station. And the data which be concerned by user can freely generate form, curve chart, histogram, etc.

3 Multiple warming safeguard: can set multiple alarming types, such as out-of-limit, misoperation, communication failure, environment failure, equipment installation failure, etc., and also can configure performance parameters, so that generate performance warming event, such as overvoltage and overcurrent event.

4 Forecast electricity generation in short time: forecast generating capacity in short on the basis of atmosphere and field operation data.

5 Recall historical events and excavate failure: support recalling failure, so that can show the generating process of failure intuitively, and provide event service for upper viewing and analysis. It is convenient for user to track events via filter the events on the basis of type, time, operator, or other conditions.